Description

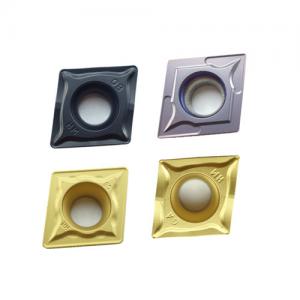

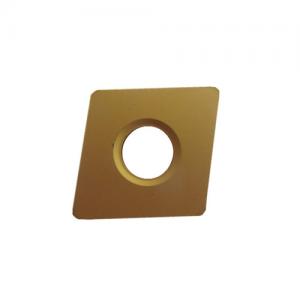

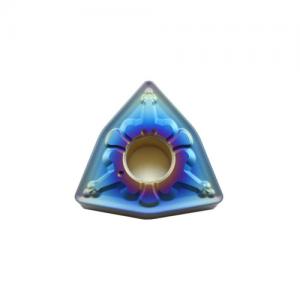

Tungsten Carbide Wear Parts

Material: High-grade tungsten carbide (WC-Co), with optional cobalt (Co) content adjustments (6%-20%) for customized hardness and toughness.

Key Features:

Extreme Hardness (HRA 90+): Superior wear resistance, 6-10x longer lifespan than steel parts.

Corrosion & Heat Resistance: Stable performance in harsh environments (up to 1000°C).

Precision Engineered: CNC-machined or sintered to tight tolerances (±0.01mm).

Customizable: Available in various grades (YG6, YG8, etc.) and geometries (inserts, sleeves, nozzles, etc.).

Applications:

Oil & Gas: Wear rings, choke valves, downhole tools.

Advantages Over Alternatives:

1.Outlasts steel/ceramic parts in abrasive conditions.

2. Reduces downtime and replacement costs.

3. Compatible with OEM equipment (provide drawings for tailored solutions).

Material: High-grade tungsten carbide (WC-Co), with optional cobalt (Co) content adjustments (6%-20%) for customized hardness and toughness.

Key Features:

Extreme Hardness (HRA 90+): Superior wear resistance, 6-10x longer lifespan than steel parts.

Corrosion & Heat Resistance: Stable performance in harsh environments (up to 1000°C).

Precision Engineered: CNC-machined or sintered to tight tolerances (±0.01mm).

Customizable: Available in various grades (YG6, YG8, etc.) and geometries (inserts, sleeves, nozzles, etc.).

Applications:

Mining & Drilling: Crusher liners, drill bits, road milling picks.

Industrial Machinery: Pump seals, valve seats, extruder screws.

Agriculture: Trencher teeth, harvester blades.Oil & Gas: Wear rings, choke valves, downhole tools.

Advantages Over Alternatives:

1.Outlasts steel/ceramic parts in abrasive conditions.

2. Reduces downtime and replacement costs.

3. Compatible with OEM equipment (provide drawings for tailored solutions).